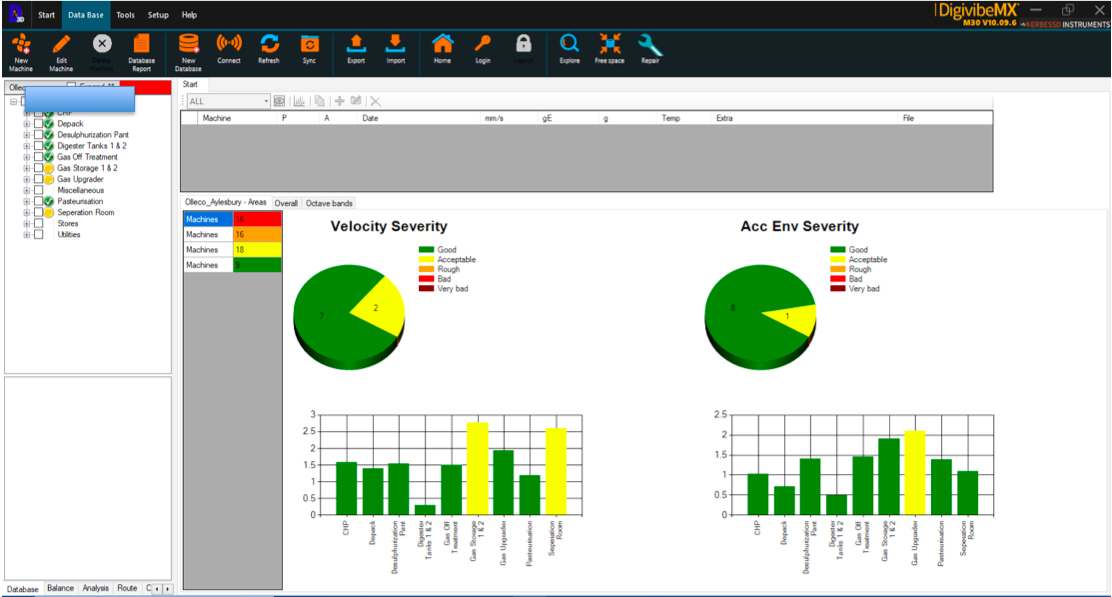

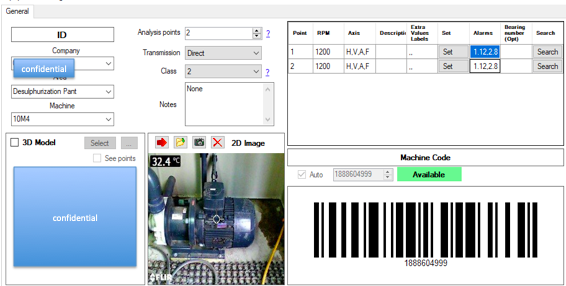

Given that this site was relatively new; the asset register was used to quickly build the CM database into the DigiVibe CM database. Information was available to accurately define the monitoring techniques and frequency for over 90% of the machinery; predominantly using route-based Vibration Analysis and IR Thermography on a monthly basis.

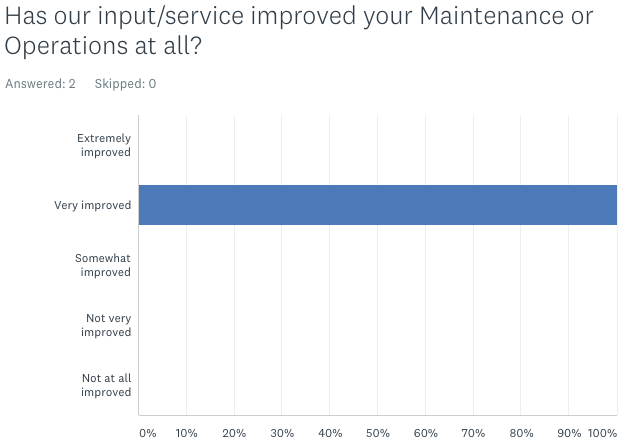

This meant that we were able to carry out routine monitoring on the majority of equipment on the 2nd visit; we found faults and made money-saving recommendations almost straight away.

The remaining equipment required alternate techniques and fixed accelerometers, which are being implemented gradually as time allows during the scheduled visits (rather than our client incurring additional labour charges).