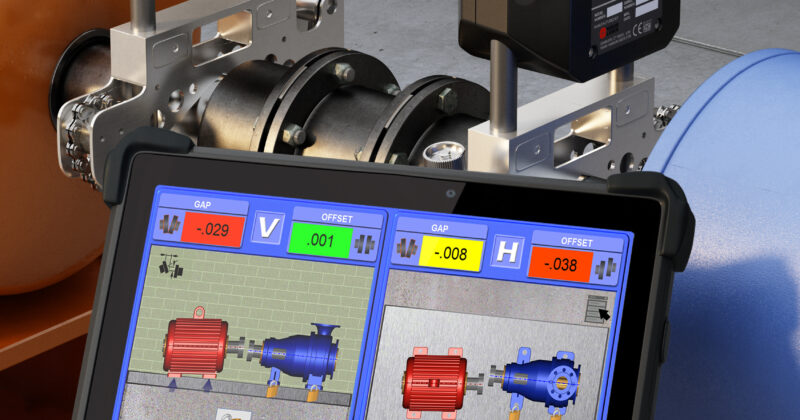

At CBM Partners, we believe success in reliability doesn’t come from equipment alone – it comes from partnership. Where typical online suppliers stop at the sale, we stay engaged, delivering expert-led condition monitoring and energy optimisation solutions backed by real-world support. Our engineers work alongside your team, providing tailored advice, hands-on training, and site services to ensure your equipment delivers lasting results. With competitive terms and a commitment to your goals, we help you build a stronger, more resilient operation.

Because when you’re protecting critical assets, you need more than convenience – you need confidence